Stereolithography SLA

NEXAMS Leading the Way in Stereolithography SLA and Additive Manufacturing Solutions

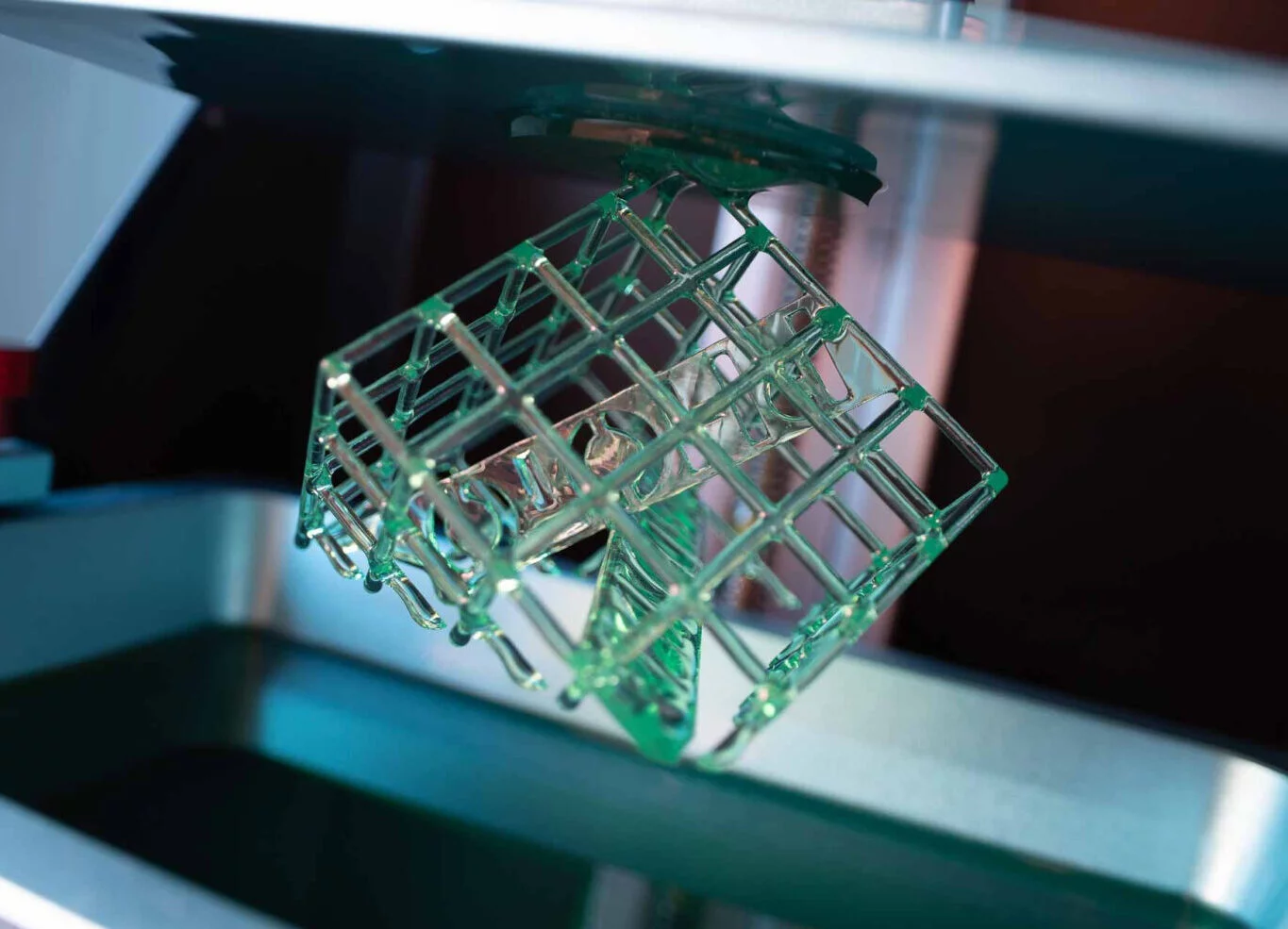

Stereolithography SLA is a revolutionary additive manufacturing process that transforms digital designs into physical components with exceptional precision and detail. At NEXAMS, we specialize in delivering high-quality SLA 3D printing services that combine laser technology with advanced resins to produce functional prototypes and end-use parts. Unlike traditional manufacturing, stereolithography SLA uses a UV laser to cure liquid resin layer by layer, building parts with smooth finishes and intricate geometries.

This process, also known as SLA additive manufacturing, is part of a wider family of rapid prototyping methods and remains one of the most accurate forms of resin 3D printing available today. Whether you need custom models for medical devices, functional prototypes for mechanical testing, or lightweight designs for aerospace applications, NEXAMS ensures consistent results with state-of-the-art SLA prototyping systems. Our trusted network of suppliers and reliable vendors enables us to bring local expertise closer to you, making sourcing simpler and more effective for industries that depend on support from dependable partners.

Our expertise includes resin 3D printing, light projection 3D printing, and liquid resin 3D printing, all optimized for efficiency and reliability. By blending engineering know-how with SLA 3D printing, we empower industries with faster turnaround times, reduced design risks, and superior quality. Clients benefit from ethical partnerships with manufacturers, suppliers, and vendors who care about sustainable solutions, as well as from nearby support teams that ensure projects are handled with responsibility and trust.

Benefits of Technology

High precision and fine detail unmatched in other rapid prototyping methods.

Smooth surface finish that minimizes the need for post-processing.

Ability to create complex internal structures using SLA prototyping.

Wide range of material choices for aerospace, automotive, and medical devices.

Cost-effective for small production runs compared to injection molding.

Supports reverse engineering projects with exceptional dimensional accuracy.

Enables composite manufacturing where lightweight and strong properties are required.

Compatible with vacuum casting for mold preparation and hybrid production approaches.

Stereolithography SLA’s combination of precision, scalability, and versatility ensures that industries adopting SLA additive manufacturing achieve better efficiency, lower costs, and quicker design iterations. This is why many suppliers and manufacturers across different sectors rely on NEXAMS. By collaborating with local vendors and maintaining nearby assistance channels, we extend helpful support that goes beyond technology—it ensures decision-makers feel confident about their choices and long-term strategies.

Industrial Application and Use Cases

Automotive: Functional prototypes, dashboards, complex geometries.

Aerospace: Lightweight custom tooling, airflow testing models.

Medical Devices: Custom surgical guides, dental aligners, hearing aid shells.

Jewelry: Castable resins enabling intricate designs for investment casting.

Consumer Electronics: Housings, ergonomic testing prototypes.

Industrial Engineering: Custom fixtures, molds, and mechanical equipment testing.

Art & Design: Sculptures, figurines, and fine-detail models.

NEXAMS integrates stereolithography SLA with reverse engineering and rapid prototyping to provide clients with comprehensive manufacturing solutions. The technology seamlessly complements composite manufacturing, resin 3D printing, and even vacuum casting for extended production needs. Businesses often make ethical sourcing decisions by working with trusted suppliers and manufacturers, knowing that local and nearby vendors can provide quick support when time-sensitive projects require immediate attention.

Material Used in Technology

Standard Resins: Ideal for models, prototypes, and cosmetic designs.

Tough Resins: For durable parts with greater mechanical strength.

Flexible Resins: Mimicking rubber-like properties for bending and elasticity.

High-Temperature Resins: For aerospace and automotive components requiring heat resistance.

Clear Resins: Perfect for optical clarity in medical devices and lenses.

Castable Resins: Specially designed for jewelry and dental molds.

With SLA additive manufacturing, these photopolymer resins allow industries to create functional parts that meet specific needs, whether in acrylic polycarbonate replacements, polycarbonate acrylic blends, or custom formulations optimized for end-use. Ethical decision-making is supported by vendors and suppliers who share responsibility with manufacturers, making it easier for companies to rely on local expertise and nearby support without delays.

How Costing Works

Costing in stereolithography SLA depends on resin type, part size, build orientation, and post-processing needs. Unlike injection molding, which requires expensive tooling, SLA prototyping offers a flexible and affordable path for small batch production. The efficiency of laser-based 3D printing reduces waste, while SLA rapid prototyping shortens development cycles.

NEXAMS leverages vacuum casting and resin 3D printing alongside SLA 3D printing to optimize costs for clients. This hybrid approach ensures affordability while maintaining the integrity and precision demanded by industries such as aerospace, automotive, and medical devices. With trustworthy vendors and consistent suppliers, combined with local support, clients are reassured that their investment aligns with both financial and ethical standards. This transparent relationship with manufacturers guarantees long-term value.

Alternative Technical Suggestion

Selective Laser Sintering (SLS): Strong thermoplastic materials for functional parts.

Fused Deposition Modeling (FDM): Cost-effective plastic prototyping for larger builds.

Digital Light Processing (DLP): Faster cure rates using light projection 3D printing.

PolyJet Printing: Multi-material printing for prototypes with complex finishes.

CNC Machining: Preferred for metal prototypes and mechanical equipment requiring high load tolerance.

While alternatives exist, stereolithography SLA remains the most reliable solution for industries demanding fine details, rapid prototyping, and smooth surface finishes. Companies that value trusted suppliers, experienced manufacturers, and ethical vendors will find that NEXAMS combines technology with human-centered support. By connecting with local and nearby partners, businesses gain reliable assistance to make balanced and future-ready decisions.

FAQs

Q: What is stereolithography SLA?

A: It is a laser-based 3D printing process that cures liquid resin layer by layer to build precise and detailed parts, also known as SLA additive manufacturing.

Q: How does SLA differ from other 3D printing methods?

A: Unlike FDM or SLS, SLA uses a laser to cure liquid resin, enabling smoother finishes, finer details, and resin-specific properties.

Q: What industries benefit most from SLA 3D printing?

A: Aerospace, medical devices, automotive, jewelry, and consumer electronics benefit due to the ability to rapidly prototype and reverse engineer functional components.

Q: Can stereolithography SLA be combined with vacuum casting?

A: Yes, SLA prototypes are often used to create master patterns for vacuum casting, expanding production capabilities.

Q: What role does rapid prototyping play in SLA technology?

A: SLA rapid prototyping reduces time to market, allows iterative design, and ensures high-fidelity testing before mass production.

Q: How is SLA used in composite manufacturing?

A: SLA enables creation of molds and detailed patterns for composite layups, improving efficiency and structural performance.

Q: Is stereolithography SLA suitable for mechanical equipment?

A: Yes, SLA parts can serve as prototypes for testing form, fit, and function in mechanical equipment development.

Q: What are the advantages of resin 3D printing?

A: Resin 3D printing produces smooth, accurate parts with high resolution, making it ideal for detailed components.

Q: What is SLA prototyping best for?

A: SLA prototyping excels in detailed prototypes, reverse engineering, and applications where precision is critical.

Q: Why choose NEXAMS for stereolithography SLA?

A: NEXAMS combines expertise in SLA 3D printing, resin materials, and additive manufacturing to provide reliable, cost-effective, and high-quality solutions. Our partnerships with ethical suppliers, responsible manufacturers, and reliable vendors, combined with local and nearby support, ensure that every client receives not only technology but also genuine human care.

Q: What are the maximum estimated shipping times from the factory to global regions for Brazing parts via sea and air?

By Sea: Asia: 15–20 days, Europe: 25–35 days, North America: 30–40 days, South America: 35–45 days, Middle East: 14–18 days, Africa: 20–28 days, Oceania: 22–30 days

By Air: Asia: 1–3 days, Europe: 3–5 days, North America: 4–6 days, South America: 5–7 days, Middle East: 1–2 days, Africa: 3–5 days, Oceania: 4–6 days